The features and working theory of laser cutting

--- Laser knowledge popularization

As a new technology that only appeared in modern times, laser cutting has been widely used in various industries so far, including metal cutting, glass cutting, and engraving.

A laser is a type of light that, like electroluminescence in nature, that caused by the transformation of atoms (molecules or ions) by spontaneous emission. Although laser light is very light, it is significantly different from ordinary light. The laser only relies on spontaneous emission for a very short initial period, and the subsequent process is completely determined by the excitation radiation, so the laser has a very pure color and almost no divergence directionality, and the luminous intensity is very high. The laser also has high coherence, high intensity, and high directivity, after the laser generates laser light, it is transmitted by the mirror and irradiated to the processed object through the collecting mirror so that the processed object (surface) is subjected to strong thermal energy and the temperature increases sharply. Due to the high temperature, the point melts or evaporates rapidly, and the trajectory of the laser head to used for processing purposes.

Items cut by laser machines, such as balsa wood boards, non-woven fabrics, etc., can be cut without loose edges, no deformation, and no hardening, and it can cut any complex shape to achieve high-efficiency and low-cost work. Meanwhile, design graphics on the computer can realize cut any size material such as lace, and it can change the engraving at any time, as long as they are designed on the computer.

The laser processing technology is mainly divided into two working modes: laser cutting and laser engraving. For each working mode, there are some differences in the operation process.

So what is the working principle of the laser cutting machine? Here is the explanation for you as follows:

1. Laser engraving

Laser engraving is mainly working on the surface of objects that are divided into bitmap engraving and vector engraving.

2. Bitmap engraving

Bitmap engraving first needs to hang up the graphics that ready to be engraved and convert them into monochrome BMP format in PHOTOSHOP, and then open the graphics files in the dedicated laser engraving in the cutting software. Set the appropriate parameters according to the processed material, and then click to run, the laser engraving machine will engrave according to the dot matrix effect generated by the graphics file.

3. Vector engraving

Use Coreldraw, AutoCad, Iluustrator and other vector software for typesetting and design, export graphics to PLT, DXF, AI format. and then use the special laser cutting and engraving software to open the graphics file and transfer it to the laser engraving machine for processing.

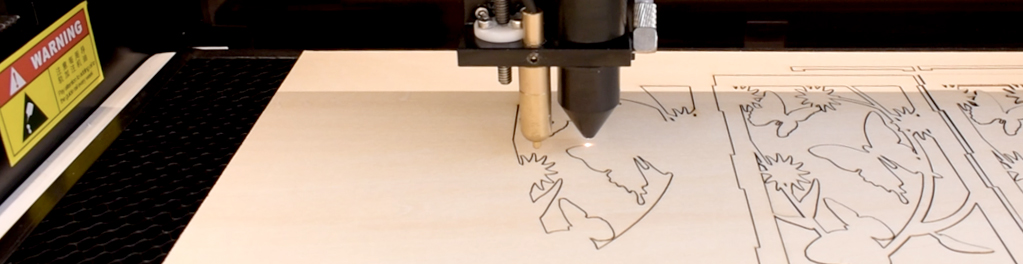

4. Laser cutting, we can understand it is the separation of the edges.

For such processing purposes, we should first make graphics in the form of vector lines in CORELDRAW, AUTOCAD, and pneumatic marking machines, and then save them as corresponding PLT and DXF formats. Use the laser cutting machine operating software to open the file, set the parameters such as power and working speed, after receiving the instructions from the computer, the laser cutting machine will automatically cut according to the flight path generated by the software.

5. The features of laser cutting

As a new processing method, laser processing is gradually widely used in the leather, textile and garment industries due to its advantages of precise processing, fast speed, simple operation and high degree of automation. Compared with the traditional cutting method, the laser laser cutting machine is not only cheaper, less consumables, but also has no mechanical pressure on the workpiece. The effect of cutting products is better, the precision is delicate and cutting speed is faster, also the operation safety and maintenance are simple.