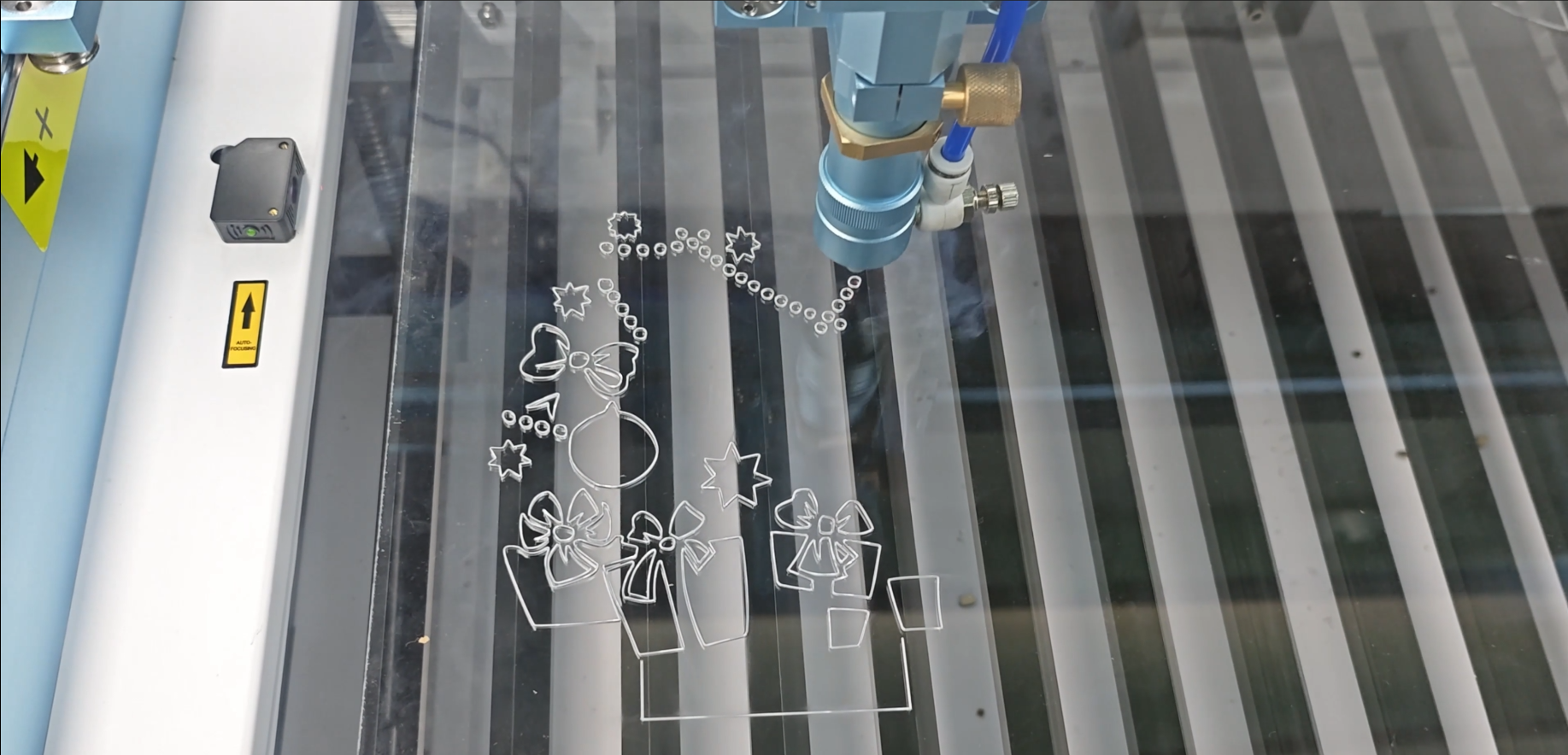

[Acrylic] Application of laser cutting machine in acrylic material cutting

Laser cutting machine is a kind of equipment that uses high energy density laser beam to process materials precisely. It can achieve efficient and high precision cutting of materials. It is widely used in the processing of non-metal, plastic, wood, glass, ceramic and other materials. Especially in the cutting of acrylic materials, laser cutting machine shows its unique advantages.

Advantages of laser cutting acrylic

1. High cutting accuracy

The laser cutting machine uses a focused laser beam to cut, and its cutting width is usually within 0.1mm. It can achieve extremely high processing accuracy and is particularly suitable for cutting products with complex patterns and high detail requirements.

2. Smooth cutting edge

Since laser cutting is a non-contact process, the laser beam melts and vaporizes the acrylic surface at high temperature without mechanical stress, so the edge after cutting is very smooth and no post-grinding is required.

3. Strong flexibility

The laser cutting machine is controlled by system and can quickly switch patterns and sizes without the need for additional mold making. It is suitable for small-batch, multi-variety processing needs, especially personalized customized products.

4. Low heat affected zone

The heat-affected zone of laser cutting is small, which avoids deformation and cracking of the material due to high temperature and can maintain the appearance and mechanical properties of acrylic.

Application fields of laser cutting acrylic

Advertising signs: production of various acrylic signs, luminous characters, display stands, etc.

Handicraft production: used for engraving acrylic decorations, medals, and souvenirs.

Architectural decoration: acrylic partitions, ceiling decoration, wall design.

Electronic products: acrylic housing, panel, display bracket, etc.

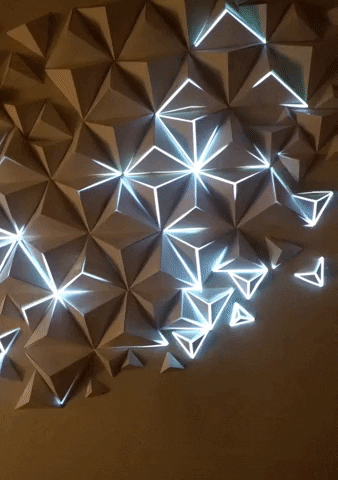

![[Cardboard] Laser cutting illuminates new creative fields of cardboard](/uploads/upload/20250106/25010614143K09.jpg)

![[Fabric] Good-Laser: A Precise Tool for Fabric Cutting](/uploads/upload/20241216/2412161QPaX.png)