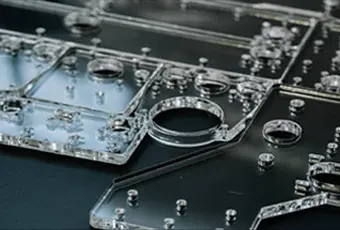

CO2 Laser Engraving Machine Acrylic Cutting Performance

Laser engraving machines have become essential in industries where precision cutting and engraving of materials are needed, particularly for non-metals like acrylic. Acrylic, due to its clarity, versatility, and relative ease of cutting, is widely used across a range of industries, from signage to art. However, cutting acrylic using laser engraving machines comes with technical challenges and performance factors that can vary significantly depending on machine specifications, laser type, power settings, and cooling methods. Good-Laser will provide a deep dive into the technical factors impacting laser engraving machine performance for acrylic cutting.

1. Laser Types and Their Impact on Acrylic Cutting

The primary types of lasers used in acrylic cutting are CO2 lasers and fiber lasers. CO2 lasers are the most common choice for cutting and engraving acrylic due to their wavelength, typically around 10.6 micrometers, which is highly absorbed by acrylic materials. Fiber lasers, which operate at around 1.06 micrometers, are less suitable for cutting acrylic since the material is more transparent to this wavelength, leading to ineffective absorption and poor cutting performance.

Key Characteristics of CO2 Lasers for Acrylic Cutting:

- Wavelength Absorption: The 10.6-micrometer wavelength of CO2 lasers is well-suited for thermal absorption in acrylic, which promotes efficient melting and smooth cutting.

- Beam Quality: High-quality CO2 laser beams enable better control over the cut, minimizing charring and edge distortions that can occur due to thermal effects.

- Power Ranges: For thick acrylics, CO2 lasers with higher power (60W to 150W) are recommended to achieve smooth cuts without multiple passes. However, higher power also means increased heat input, which can impact edge quality.

2. Power Settings and Their Influence on Acrylic Cuts

Laser power settings are one of the most critical factors affecting cut quality in acrylic. Lower power settings typically lead to slow cutting speeds and require multiple passes, while excessively high power may result in melting, charring, or warping of the acrylic.

- Low Power (10W - 30W): Ideal for thin acrylic sheets (1-2 mm) and primarily for engraving purposes. Low power settings reduce the risk of edge discoloration or over-melting.

- Medium Power (30W - 60W): Suitable for moderate thicknesses (3-5 mm) where single-pass cuts are possible, allowing for a balance between speed and quality.

- High Power (60W and above): Recommended for cutting thick acrylic sheets (up to 10 mm and beyond). However, the heat-affected zone (HAZ) becomes more pronounced at these settings, requiring additional cooling or adjustments in speed to prevent heat buildup.

For most projects, a power setting between 50% to 70% of the machine' s maximum power is optimal. Adjusting this range with fine-tuning of cutting speed can enhance both cut quality and edge finish.

3. Cutting Speed and Its Effects on Edge Quality

Cutting speed is closely linked to power settings and must be carefully adjusted to balance quality with cutting time. Too high a speed can cause incomplete cuts or ragged edges, while too slow a speed can lead to burning and undesirable melting.

- High Speed: Best for thinner acrylic sheets and engravings where precision isn' t as critical, such as in creating patterns or designs that don' t require deep cuts.

- Moderate Speed: Recommended for general-purpose cutting of acrylic between 3 mm and 5 mm thick, as it offers a clean cut while controlling thermal stress on the material.

- Low Speed: Necessary for cutting thick acrylic sheets, especially when high power is required. Reducing the speed allows the laser sufficient time to fully penetrate the material without excessive re-melting or warping.

The ideal speed-power balance depends on the acrylic type and thickness. For instance, extruded acrylic generally cuts faster than cast acrylic, but cast acrylic often yields higher quality and durability for intricate designs.

4. Focus Lens and Spot Size Considerations

The lens used in a laser engraving machine determines the spot size, which directly affects the detail and precision of the cut. Lenses with shorter focal lengths (e.g., 1.5 inches) create a smaller, finer spot, resulting in higher precision, but are limited in their cutting depth.

- 1.5-Inch Focal Length: Ideal for detailed cuts and engravings on thin acrylic sheets. This short focal length provides excellent resolution and reduces kerf width (the width of the cut line), which is ideal for intricate designs.

- 2.0-Inch Focal Length: Offers a balance between cutting depth and precision. It' s versatile for both engraving and cutting mid-thickness acrylic (3-5 mm) without significant loss in edge quality.

- 2.5-Inch and Above: Suitable for deep cuts in thick acrylic sheets. A longer focal length allows the laser to penetrate deeper but sacrifices some precision due to a larger spot size.

5. Cooling Systems and Their Role in Acrylic Cutting

Acrylic is highly susceptible to thermal distortion, so managing heat dissipation is essential for maintaining quality. Many laser engraving machines are equipped with cooling systems that help prevent overheating.

- Air Assist: An air assist system directs a stream of air or gas to the cutting area, which not only reduces the heat but also removes debris, leading to cleaner cuts.

- Water Cooling: High-powered CO2 lasers often require water cooling to maintain stable performance, especially during prolonged cutting sessions. Proper water cooling prevents overheating, which can cause cracking or warping in acrylic.

- Chiller Systems: Chillers are often used with high-wattage lasers to maintain the laser tube' s optimal temperature. A stable tube temperature results in consistent power output, leading to uniform cuts.

Proper cooling is especially critical for thick acrylic cuts, where heat buildup can degrade the material and negatively impact both cut quality and machine performance.

6. Cut Quality, Edge Finish, and Common Challenges

The quality of a laser-cut edge on acrylic is a key performance indicator. The goal is to achieve a clear, polished edge without residue or charring. However, several common challenges can arise:

- Heat-Affected Zone (HAZ): High power settings can result in a larger HAZ, leading to melted edges or slight discoloration. Minimizing HAZ requires optimizing both speed and power and may involve post-processing for edge clarity.

- Cracking: If the machine lacks sufficient cooling or if settings are incorrect, acrylic can crack during or after cutting due to residual stress.

- Discoloration: Overheating can cause discoloration or a burnt appearance along the cut line. Using air assist and adjusting power can mitigate this issue.

Conclusion

Laser engraving machines, particularly those with CO2 lasers, are excellent tools for cutting acrylic, but achieving optimal performance requires understanding and managing numerous technical factors. From selecting the right power and speed settings to choosing the appropriate focal length and implementing effective cooling solutions, each variable influences the quality of the final cut. By carefully calibrating these factors, users can ensure high-quality, precise cuts in acrylic, enabling a range of applications from fine art to industrial components.