Precautions for Using 3D Wood Laser Cutter for Education

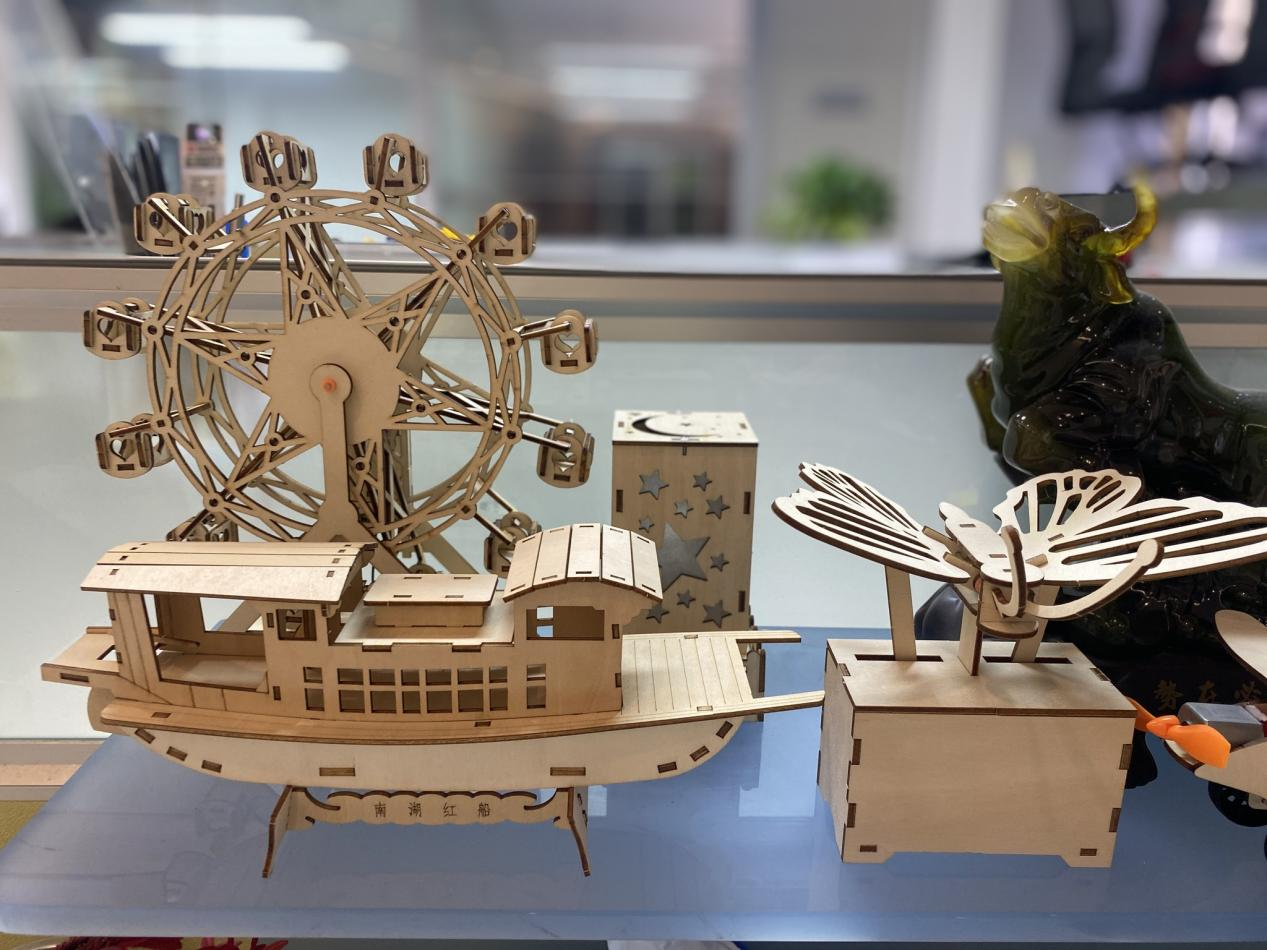

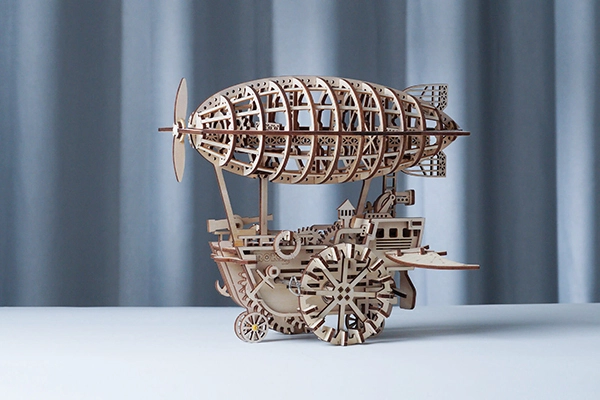

Laser cutters have changed the way students and educators approach woodworking and design in educational settings. With the ability to create complex designs with high precision, they have become an indispensable tool for STEM and art education. However, like any powerful tool, they come with a set of risks and precautions that must be considered to ensure the safety of the equipment, longevity, and quality of your projects. In this blog post, Good-Laser, a high performance laser cutter for education exporter , will share the precautions for using 3D wood laser cutter in educational settings.

1. Proper Training and Supervision

The most important precaution is ensuring that all users—whether students, teachers, or other staff members—receive adequate training on the operation of the 3D wood laser cutter. This training should cover:

- Safety protocols: Understanding the risks of high-powered lasers, fire hazards, and chemical exposure.

- Machine operation: How to safely power on/off the machine, load and position materials, and initiate cutting or engraving jobs.

- Emergency procedures: Knowing what to do in the event of a fire, electrical malfunction, or other hazards.

- Laser settings: Educating users on the various power settings and their effects on wood types, thickness, and engraving depth.

Without proper training, the likelihood of accidents increases, and the risks associated with laser cutters become significantly more pronounced.

2. Workspace Preparation and Ventilation

Laser cutters emit smoke, fumes, and particulate matter during the cutting process. In an educational environment, ensuring proper ventilation is essential to prevent respiratory issues and the buildup of flammable gases.

- Ventilation: Ensure that the workspace is equipped with a high-quality exhaust system, ideally connected to an external vent to expel harmful gases. Many laser cutters come with a built-in fume extraction system, but additional ventilation may be necessary, especially in large, high-volume classrooms.

- Fire prevention: Place fire extinguishers within reach, as wood can catch fire under certain conditions. Laser cutters can cause wood to smolder, and even if the laser stops, the wood may continue to burn.

- Material handling: Ensure that any materials nearby are non-combustible and stored away from the laser cutter. Wood shavings and sawdust can be highly flammable, so cleaning the workspace regularly is crucial.

3. Material Selection and Safety

One of the most important aspects of operating a 3D wood laser cutter is the selection of materials that are compatible with the machine and safe to use. Some materials, such as treated woods, contain harmful chemicals that can release toxic gases when cut. Others, like MDF or plywood, may contain formaldehyde, which can be hazardous when vaporized by the laser.

- Wood Type: Only use clean, untreated wood or wood that is labeled as safe for laser cutting. Common options include birch, maple, or pine. Avoid using composite materials or anything that might contain harmful chemicals.

- Avoid Toxic Finishes: Do not use wood treated with stains, varnishes, or glues that are not specifically designed to be laser-safe. Many commercial finishes release harmful fumes when heated by the laser.

- Laser Settings: Different types of wood require different laser settings to avoid burning, warping, or other damage. The focus should be on controlling power and speed to match the material' s properties. Too much power or too slow a speed could cause excessive charring or even fires.

Educators should ensure that students are taught to check the material specifications and adjust settings accordingly to maintain both safety and quality in their projects.

4. Proper Machine Setup and Calibration

To ensure the laser cutter operates effectively and safely, regular maintenance, calibration, and setup checks should be performed. This includes:

- Lens and mirror cleaning: Over time, the laser' s lens and mirrors can accumulate debris, reducing the effectiveness of the beam and potentially causing malfunctions. Clean the lens regularly according to manufacturer instructions to ensure that the laser is focusing properly.

- Focus adjustments: The laser' s focal point is critical to achieving clean cuts. Ensure that the laser head is correctly calibrated for each material and thickness of wood being used. Many machines come with automatic focus adjustments, but manual checks may still be necessary.

- Software and firmware updates: Ensure that the software used to design and send jobs to the laser cutter is up-to-date. Outdated firmware or software can result in improper cutting paths, reduced precision, and increased wear on the machine.

- Testing the setup: Before beginning any major project, always perform a test cut on a scrap piece of wood to verify that the settings are correct and the material is being cut as intended.

5. Monitoring and Post-Cut Handling

Even after the laser cutter has completed its operation, it is essential to follow safety precautions when handling the cut wood and ensuring the area is safe.

- Post-cut inspection: Check for any areas where the cut edges might still be smoldering. If a piece is still hot, allow it to cool completely before handling it.

- Laser shutdown: Ensure the machine is turned off after use, and that the work area is properly cleaned and cleared of any leftover material, dust, or wood chips. Leaving wood debris inside the machine can lead to fire hazards.

- Storage of projects: Once projects are completed, store them in a dry, cool area away from flammable materials. Ensure that finished products are allowed to cool and fully settle before being handled or taken home by students.

6. Understanding and Managing Laser Risks

The laser beam itself is extremely focused and intense, capable of causing severe burns and eye injuries.

- Protective eyewear: It is mandatory for anyone operating or working near a laser cutter to wear appropriate protective eyewear that is designed to block the specific wavelength of light emitted by the laser.

- Safety barriers: Many laser cutters are equipped with safety barriers or protective enclosures that prevent exposure to the laser beam. Ensure these are always in place and in good condition during operation.

- Distance: Maintain a safe distance from the laser during operation, and never attempt to bypass safety mechanisms in the interest of speed or convenience.

Conclusion

While 3D wood laser cutters are an incredible educational tool, their power and precision come with inherent risks that require careful management. By following proper training protocols, ensuring a well-ventilated workspace, selecting safe materials, maintaining the equipment, and always adhering to safety guidelines, educators can harness the full potential of these machines while ensuring a safe, productive environment for students. As laser cutting technology becomes an increasingly important part of education, these precautions will help safeguard both the users and the equipment, fostering an atmosphere where creativity and safety go hand in hand.