Working Principle of Desktop CO2 Laser Cutter for Education

Among various types of laser cutting machines, desktop CO2 laser cutting machines are a popular choice due to their affordability, high precision, and ease of use. They allow students and educators to explore digital manufacturing, prototyping, and creative design in fields such as engineering, art, and product development. In this blog post, Good-Laser will share the working principle of desktop CO2 laser cutter for education, introducing its components, benefits, and applications in academic environments.

What is High Performance Desktop CO2 Laser Cutter for sale?

A CO2 laser cutter is a type of laser cutting machine that uses a gas mixture - primarily carbon dioxide - to generate a laser beam for cutting, engraving, or marking various materials. Unlike industrial laser cutters, desktop CO2 laser cutters are compact and designed specifically for small-scale applications, making them ideal for classrooms, workshops, and makerspaces.

Key Components of CO2 Laser Cutter for Education

1. Laser Tube: This glass tube contains a mixture of gases (CO2, nitrogen, hydrogen, and helium). When an electric current passes through, the gases get excited and produce a high-energy laser beam.

2. Power Supply: Provides the necessary voltage to excite the gas molecules and generate the laser beam.

3. Optical System: Consists of mirrors and a focusing lens that direct and concentrate the laser beam onto the material.

4. Control Panel: A user interface that allows students and educators to adjust settings such as laser power, speed, and design parameters.

5. Cooling System: CO2 laser tubes generate heat during operation, so a cooling system (typically water-based) prevents overheating and ensures stable performance.

6. Exhaust System: Removes fumes and smoke produced during the cutting or engraving process, ensuring a safe working environment.

Working Principle of Desktop CO2 Laser Cutter for Education

1. Designing the Digital File

Before cutting or engraving, students create a digital design using software such as CorelDRAW, Adobe Illustrator, or AutoCAD. The design file is then converted into a format compatible with the laser cutter (e.g., DXF, SVG, or BMP).

2. Laser Beam Generation

Once the machine receives the digital file, an electrical current excites the CO2 gas mixture inside the laser tube. This energy release produces a high-powered infrared laser beam.

3. Beam Direction and Focusing

The laser beam is guided through a series of mirrors towards the focusing lens, which converges the beam into a precise point. This focused laser beam has high thermal energy capable of cutting, engraving, or marking materials.

4. Material Interaction

When the laser beam makes contact with the material, it either vaporizes or melts the surface, depending on the laser settings and material properties. The machine moves the laser head according to the digital design, ensuring accuracy and precision.

5. Fume Extraction and Cooling

During operation, the exhaust system removes smoke and fumes to maintain air quality, while the cooling system regulates the temperature of the laser tube.

6. Final Output

Once the process is complete, students can remove the finished piece, which may be a precisely cut shape or an engraved design.

Benefits of Desktop Laser Cutter for Education

1. Enhances Creativity and Innovation

Laser cutters provide students with a powerful tool for prototyping, fostering creativity and innovation in design and engineering.

2. Improves Technical Skills

Students gain hands-on experience with CAD software, digital fabrication, and material processing, preparing them for future careers in technology and manufacturing.

3. Encourages Problem-Solving

By working with laser cutters, students learn to troubleshoot design and technical challenges, improving their problem-solving abilities.

4. Cost-Effective and Sustainable

Desktop CO2 laser cutters use minimal material waste, making them an eco-friendly and cost-effective tool for educational institutions.

Applications of Desktop CO2 Laser Cutter for Education

1. STEM Education

- Encourages hands-on learning in science, technology, engineering, and mathematics (STEM).

- Allows students to create models, prototypes, and functional components for robotics and engineering projects.

2. Arts and Design

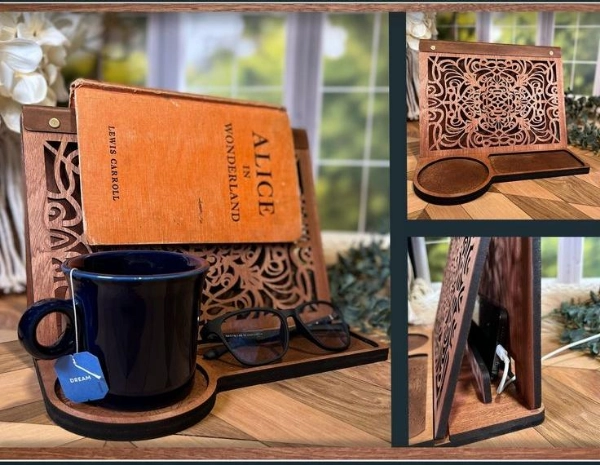

- Supports creativity in graphic design, fine arts, and product design.

- Enables intricate engraving on wood, acrylic, leather, and fabric for artistic projects.

3. Architecture and Model Making

- Assists architecture students in fabricating precise scale models.

- Enhances project presentations with laser-cut structures and designs.

4. Entrepreneurship and Business Education

- Allows students to explore product manufacturing and branding by creating custom merchandise.

- Encourages entrepreneurial skills through hands-on experience in digital fabrication.

Conclusion

The working principle of a desktop CO2 laser cutter for education revolves around generating a high-powered laser beam, directing it onto a material surface, and precisely cutting or engraving designs. These machines have transformed the way students learn and create, providing an interactive platform for exploring design, engineering, and entrepreneurship. With their increasing accessibility and affordability, desktop CO2 laser cutters are becoming indispensable tools in modern education, shaping the future of digital fabrication and hands-on learning.

Educational institutions looking to integrate laser cutting technology should consider desktop CO2 laser cutters as an investment in student creativity, skill development, and innovation. Whether for STEM projects, arts, architecture, or business applications, these machines empower students to bring their ideas to life with precision and efficiency.