Features and Types of Laser Engraving

Features of laser engraving

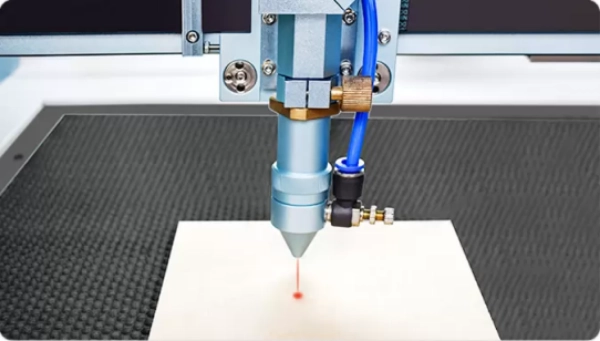

Laser engraving uses a high-energy-density laser beam to locally heat the surface of the material, causing the surface to quickly vaporize or oxidize, thereby forming a permanent pattern or text on the surface of the material. Laser engraving requires no physical contact and enables efficient, high-precision processing on a variety of materials. Laser engraving has the following salient features:

1. High precision and quality

Laser engraving has extremely high precision, reaching 0.01 mm level, so it is very suitable for engraving intricately detailed patterns and text.

During the laser engraving process, the laser beam energy is concentrated and fast, and the heat transmitted to the material to be engraved is small, so the thermal deformation of the material is also very small, ensuring the quality of the engraving.

2. Non-contact processing and environmental protection

Laser engraving uses non-contact processing, which will not cause mechanical extrusion or mechanical stress on the material, avoiding scratches and deformation that may be caused by traditional processing methods.

During the laser engraving process, the diameter of the light beam and the light spot is small, generally less than 0.5mm. The cutting process saves materials and is noiseless and pollution-free, meeting environmental protection requirements.

3. Wide range of applications

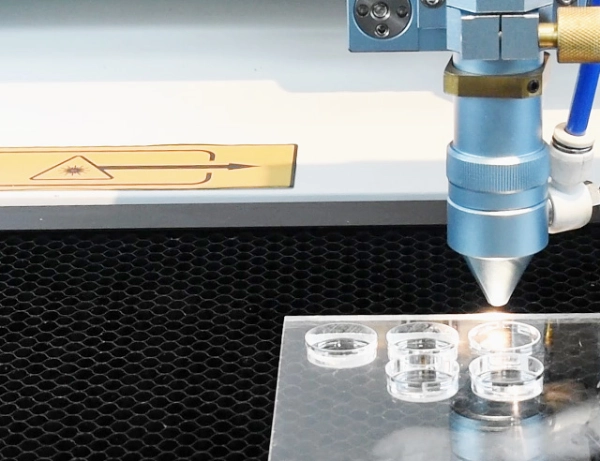

Suitable for a variety of non-metallic materials, including but not limited to wood , paper, leather, cloth, plexiglass, epoxy resin, acrylic, plastic, rubber, etc.

4. Advanced control system and software

Good-Laser engraving machine is equipped with a self-developed control system, which realizes the separate adjustment of the power of the dual laser heads, improving work efficiency and engraving quality.

The software supports input in multiple formats, such as AI, PS , BMP, JPG, DXF, DST, etc., which is convenient for users to perform graphic processing and typesetting.

The mobile APP has a one-click photo upload function. You can choose your favorite work, take a photo and upload it to start creation .

Types of Laser Engraving

1. Dot engraving:

Dot engraving is very similar to high-definition dot printing. The laser head swings left and right, engraving a line consisting of a series of dots each time. Then the laser head moves up and down at the same time to engrave multiple lines, finally forming a full-page image or text.

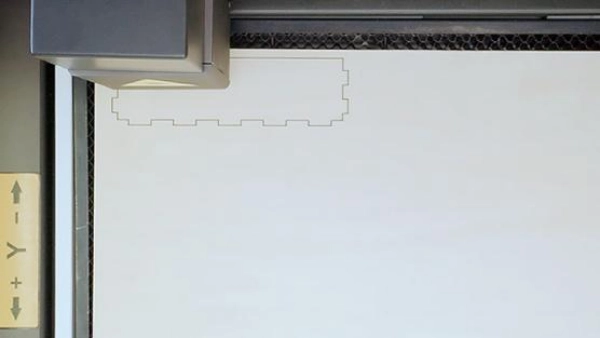

2. Vector engraving:

Vector engraving is performed on the outer contour line of the image and is usually used for penetrating cutting of materials such as wood, acrylic, and paper.

3. Mixed engraving and cutting:

Good-Laser equipment also has diversified processing capabilities such as cutting, marking, drilling, and engraving . It is highly flexible and applicable and suitable for a variety of application scenarios.

4. Embedded engraving:

In laser engraving technology, recessed engraving is a process method in which the pattern area is precisely engraved by the laser, while the surrounding background area remains intact and is not engraved. This process causes the pattern area to be recessed relative to the background area, or the color or texture of the pattern to change. This process is very common in the field of laser engraving due to its high precision and wide application.

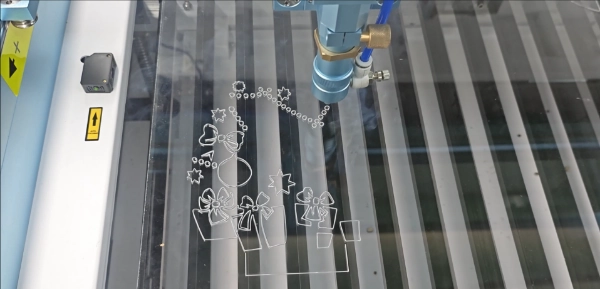

5. Photo engraving:

Photo engraving is an engraving process that uses the photo included in the design file as a template. Unscreened and unprocessed photos may affect the quality of the engraving. In order to obtain a high-quality photo engraving effect, the first step is to select a high-resolution photo with high clarity and bright image. After the selection, a series of image processing work is required to ensure that the engraved work can accurately restore every detail in the photo.

6. Relief carving:

The relief art has a very distinct three-dimensional texture, which is attributed to a special image used in the relief design process - a specially processed grayscale image. In addition, relief creation has high requirements for the thickness of the engraving material, because in order to achieve a better visual effect, it is necessary to make greater changes in the engraving depth, which naturally requires a thicker engraving medium to carry it.