How Does a Makerspace Laser Cutter Lead the Creative Trend?

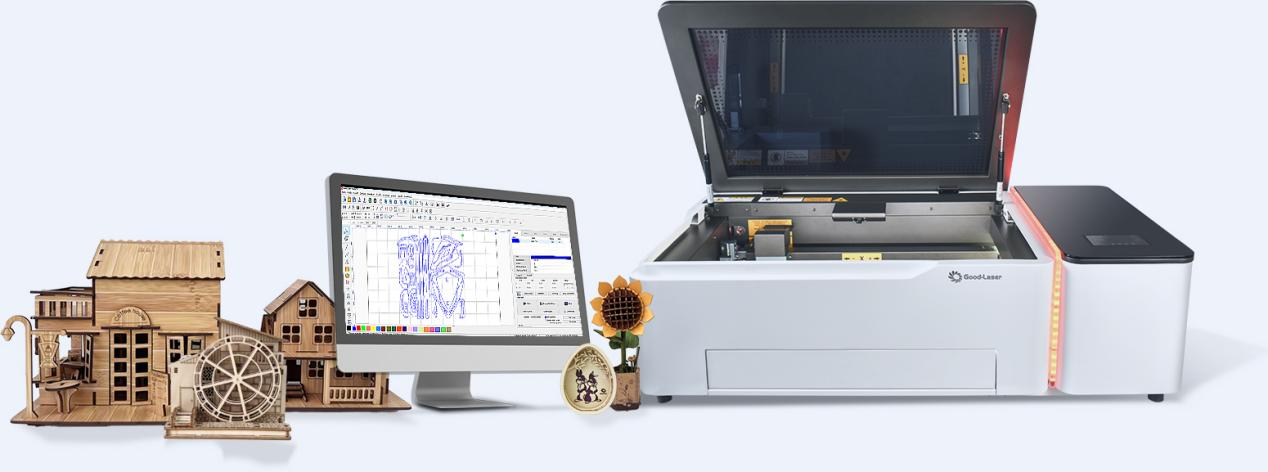

The precision, versatility and accessibility of DIY co2 laser cutters not only democratize manufacturing, but also catalyze new trends in creative expression. In this blog post, Good-Laser will share the advantages of makerspace laser cutter for sale, and how desktop co2 laser engraver can lead the creative trend by empowering makers, enabling rapid prototyping and promoting innovation across industries. We specialize in providing high-quality laser cutter for makerspace!

The Technology Behind Laser Cutting

At its core, laser cutting employs a highly focused beam of light to cut, engrave, or etch materials with incredible precision. The process relies on computer numerical control (CNC) to direct the laser, ensuring accuracy down to fractions of a millimeter. Makerspace laser cutters typically use CO2 lasers, which are versatile enough to handle a variety of materials such as wood, acrylic, leather, fabric, and even thin metals.

The process can be categorized into three primary operations:

1. Cutting: The laser beam fully penetrates the material, creating clean, sharp edges.

2. Engraving: The laser removes a surface layer, producing detailed designs.

3. Etching: Similar to engraving but less intrusive, etching alters the material's surface texture for subtle effects.

These capabilities make laser cutters indispensable for both functional and aesthetic applications, aligning perfectly with the creative ethos of makerspaces.

Empowering Individual Creators

One of the most significant impacts of laser cutters in makerspaces is their ability to empower individual creators. Before the advent of affordable laser cutting technology, precise fabrication required expensive machinery or outsourced services, limiting accessibility. Laser cutters in makerspaces have changed this dynamic by providing access to professional-grade equipment at minimal cost.

This accessibility has unleashed a wave of creativity among hobbyists, artists, and entrepreneurs. For instance:

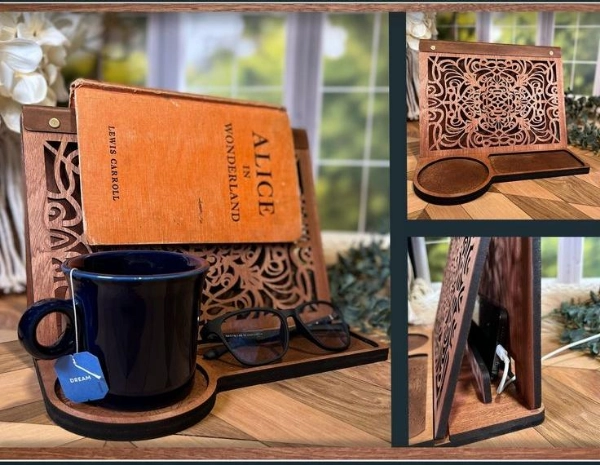

- Artists can produce intricate designs on diverse materials, elevating traditional crafts to modern art forms.

- Entrepreneurs can create prototypes or small product runs without the need for large-scale manufacturing facilities.

- DIY enthusiasts can personalize items, from custom jewelry to bespoke furniture, bringing unique visions to life.

By eliminating technical and financial barriers, makerspace laser cutters have made high-quality craftsmanship attainable for everyone.

Enabling Rapid Prototyping

In the realm of innovation, speed and iteration are critical. Laser cutters excel in enabling rapid prototyping, allowing creators to turn ideas into tangible objects in a matter of hours. Here's how they accomplish this:

1. Precision and Reproducibility: Laser cutters can execute designs with consistent accuracy, making them ideal for testing iterations.

2. Material Versatility: The ability to work with a wide range of materials enables experimentation with different textures, strengths, and aesthetics.

3. Ease of Use: User-friendly software, such as Adobe Illustrator or CorelDRAW, integrates seamlessly with laser cutters for makerspace, enabling even novice users to translate digital designs into physical prototypes.

This rapid prototyping capability has immense implications for startups and small businesses. For example, a product designer can test multiple iterations of a component in a single day, significantly reducing time-to-market. In industries like fashion, architecture, and consumer electronics, this agility fosters innovation and reduces development costs.

Driving Collaborative Innovation

Makerspaces are inherently collaborative, bringing together individuals with diverse skills and perspectives. laser cutters for makerspace enhance this collaborative environment by acting as a unifying tool that bridges disciplines. Architects, engineers, graphic designers, and hobbyists can all use the same machine to achieve vastly different objectives.

One remarkable example of such collaboration is the intersection of art and technology. Laser cutters allow artists to incorporate complex geometries and digital precision into their works, while engineers can add aesthetic flair to functional designs. This synergy has given rise to interdisciplinary projects that push the boundaries of creativity, such as interactive installations, bio-inspired structures, and hybrid products.

Additionally, makerspaces equipped with laser cutters often become hubs for workshops and training sessions, further disseminating knowledge and inspiring collective innovation.

Conclusion

Makerspace laser cutters are more than just tools; they are catalysts for creativity, innovation, and collaboration. By democratizing access to precision fabrication, enabling rapid prototyping, fostering interdisciplinary projects, and supporting sustainable practices, they are shaping the future of design and manufacturing. As makerspaces continue to grow, the role of laser cutters will undoubtedly expand, inspiring a new generation of creators to lead the creative trend!