Mr. David Ryan is engaged in custom handicraft work. With the help of Good-Laser's laser software, he is more flexible in processing orders.

With Good-Laser's laser software, custom work can now be done more flexibly and quickly

Mr. David Ryan is engaged in custom handicraft work. With the help of Good-Laser's laser software, he is more flexible in processing orders.

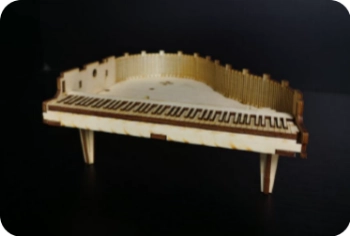

Mr. David Ryan, a master craftsman who is well versed in the art of living, has embarked on an extraordinary journey in the field of custom crafts since 2021. He not only pursues that each work can accurately convey the design concept of simplicity, cleanliness, eternity and purity, but also integrates this pursuit into every corner of life, striving to achieve a harmonious unity between work and life.

With the technical support of Good-Laser, especially the efficient and precise Light 530 laser cutting and engraving machine, Mr. Ryan's craft customization business has been revitalized as never before. This machine not only satisfies customers' ultimate pursuit of craft details with its excellent cutting and engraving capabilities, but also ensures a double leap in production efficiency and quality with its stability and durability.

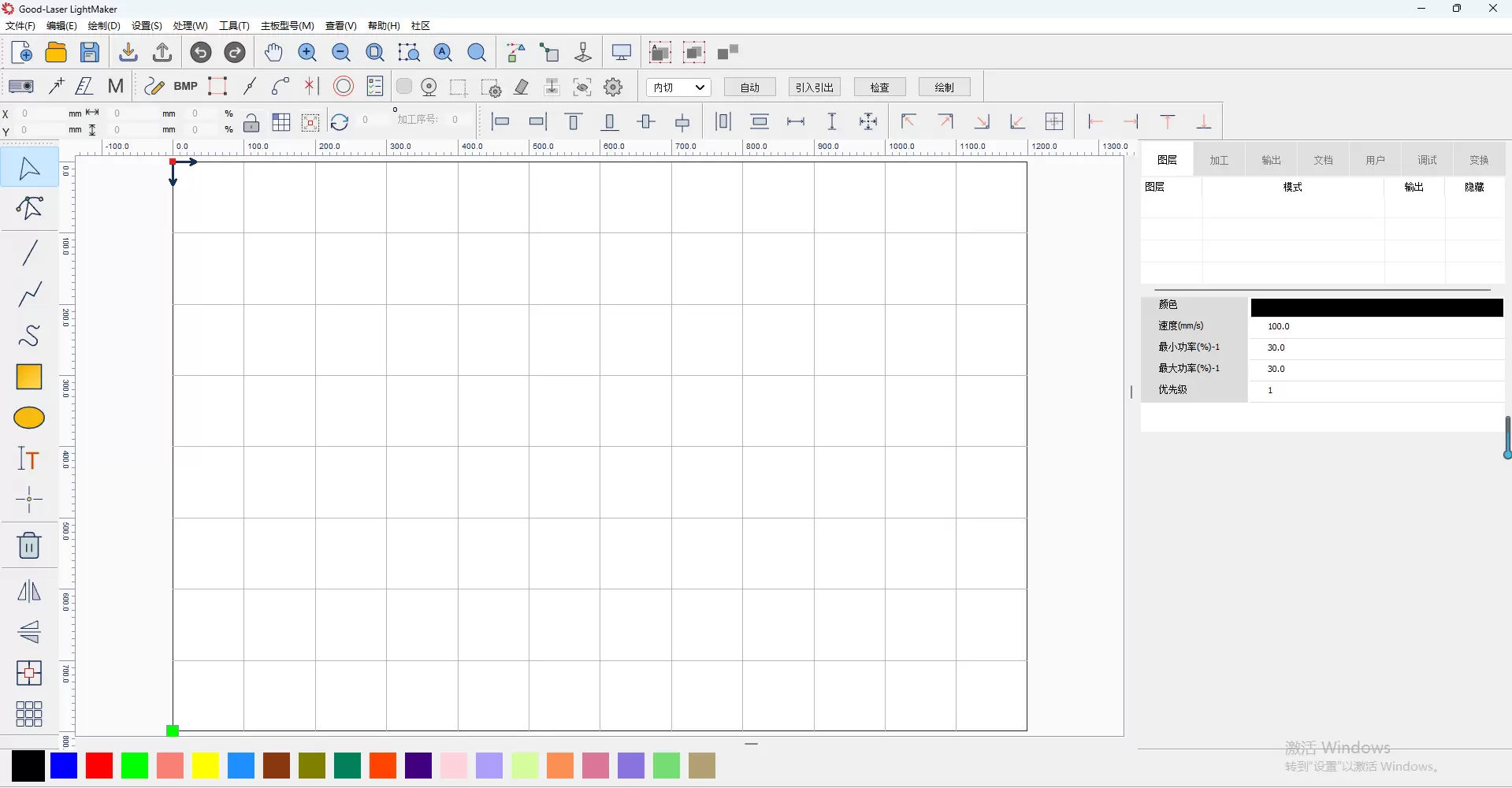

What really makes Mr. Ryan feel at ease when processing orders is the LightMaker software independently developed by Good-Laser. This software is not only user-friendly and easy to operate, but more importantly, it is seamlessly connected with the Light 530 laser cutting and engraving machine, achieving seamless connection from design to production. Mr. Ryan can easily import a variety of graphic formats provided by himself or customers into the software, whether it is vector graphics, bitmaps or other complex design drafts, and can be efficiently processed in a short time.

With the powerful support of LightMaker software, Mr. Ryan can make final adjustments and optimizations to the design directly in the software without tedious conversion or correction work. This instant modification ability greatly improves his work efficiency and ensures that each custom craft can perfectly meet the needs and expectations of customers.

What is even more amazing is that the LightMaker software is also equipped with a personalized material database function. This function allows Mr. Ryan to set the optimal cutting and engraving parameters according to the characteristics of different materials, thereby effectively managing and optimizing the entire production process. Whether it is wood, acrylic, leather or other materials, he can quickly find the most suitable setting plan to ensure that the processing quality and aesthetics of the crafts are in the best state.

The perfect combination of Good-Laser's Light 530 laser cutting and engraving machine and LightMaker software has given Mr. David Ryan's craft customization business wings to take off. He not only soars freely in the ocean of creativity, but also writes his own brilliant chapter at the intersection of technology and art.