Ton Vroon drives business forward with Good-Laser technology

Passionate about creating gifts that both celebrate and resonate with the recipient, Ton Vroon designed wedding stationery while studying at university, worked as a self-employed person, and later founded her business, which has continued to expand in direction.

Ton Vroon has now expanded to include a team of employees, processing a variety of materials to create a wide range of products, including Christmas gifts, weddings, Valentine's Day and more.

In the early days, Ton Vroon handcrafted her paper products such as invitations, service order booklets and place cards, which were hand-embellished with ribbons and other accessories.

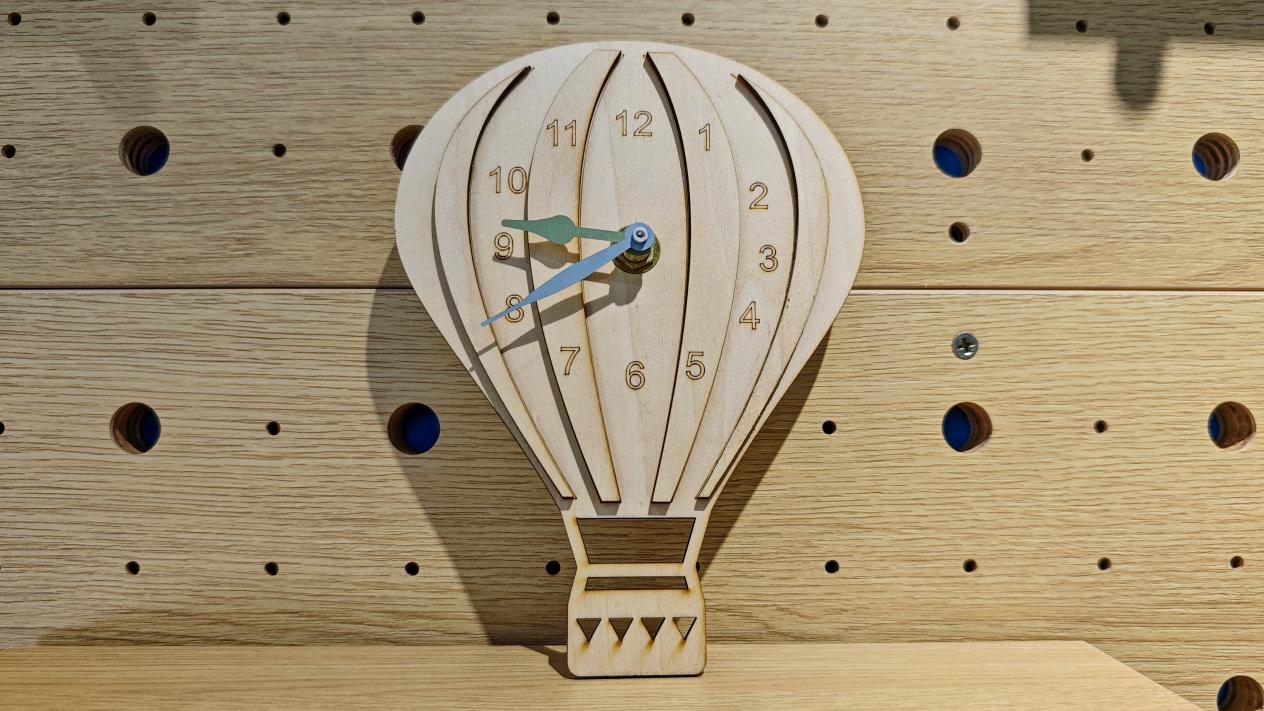

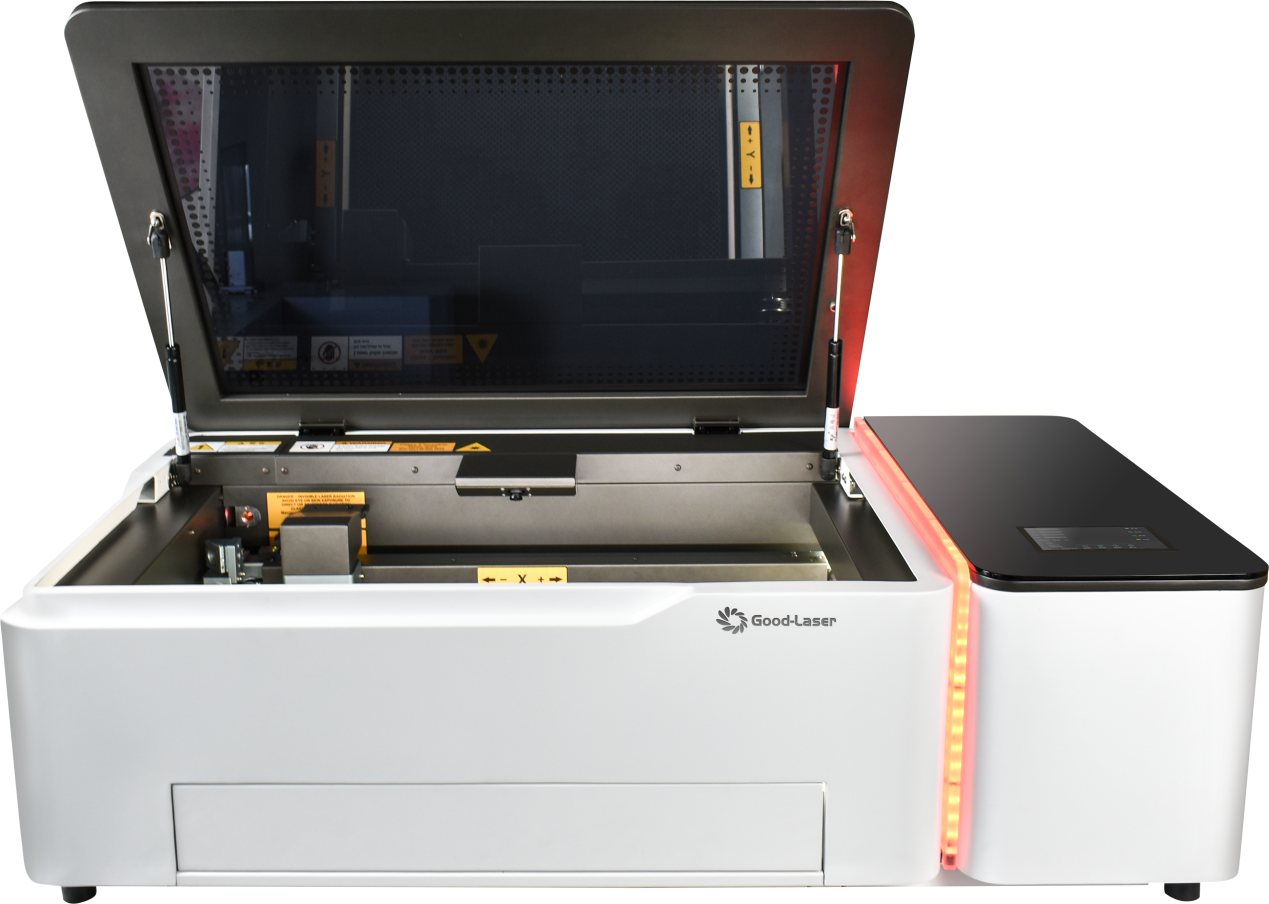

Today, Ton Vroon offers a diverse range of products, catering to a variety of markets and using a variety of materials, including wood, acrylic, faux leather, glass and steel. To manage the workload brought by the expanded product portfolio, Ton Vroon purchased a Ligth 530 laser cutting and engraving machine from Good-Laser during the busy peak period before Christmas 2022.

With the blessing of laser equipment, the quality and beauty of their products have been greatly improved. And the team at Ton Vroon is also able to achieve more detailed engraving effects than before. The speed of the laser system enables the team to quickly meet large-volume orders and provide faster delivery times. An efficient materials database enables employees to easily store and reuse established settings for future jobs.

The rotary axis accessory increases the versatility of the laser, making engraving smaller rotary jobs quick and easy, maintaining efficiency and profitability. With the Light 530's camera system, registration marks can be accurately read and materials can then be precisely cut.