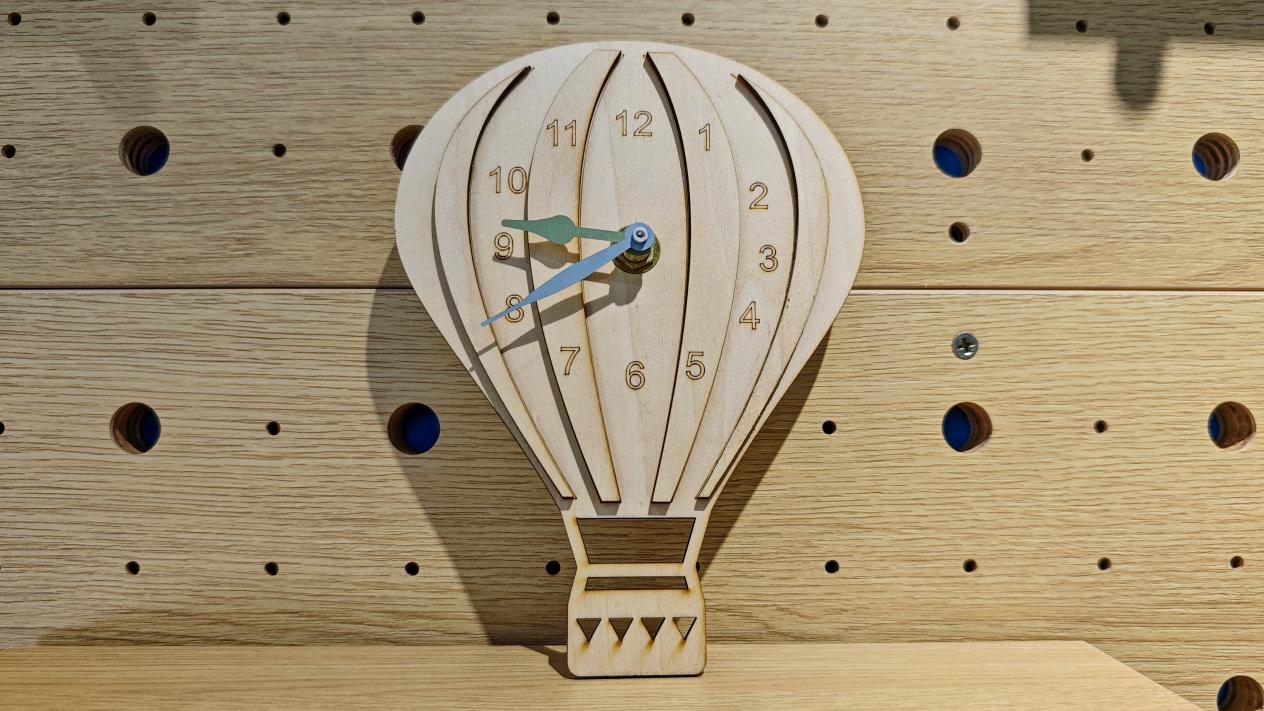

How does the Smart Laser Cutting Machine Cut Car Models?

Introduction

Welcome to the Laser Cutting Car Model Making Course! This course is designed to learn the basic principles of laser engraving, the characteristics and processing methods of wood materials, and the practical operation of using the Good-Laser Light 530 smart laser cutting machine for sale to transform the design into an actual light sign work.

Prepare materials

Hardware: Good-Laser Light 530 smart laser cutting machine, computer, workbench, vacuum cleaner, safety glasses

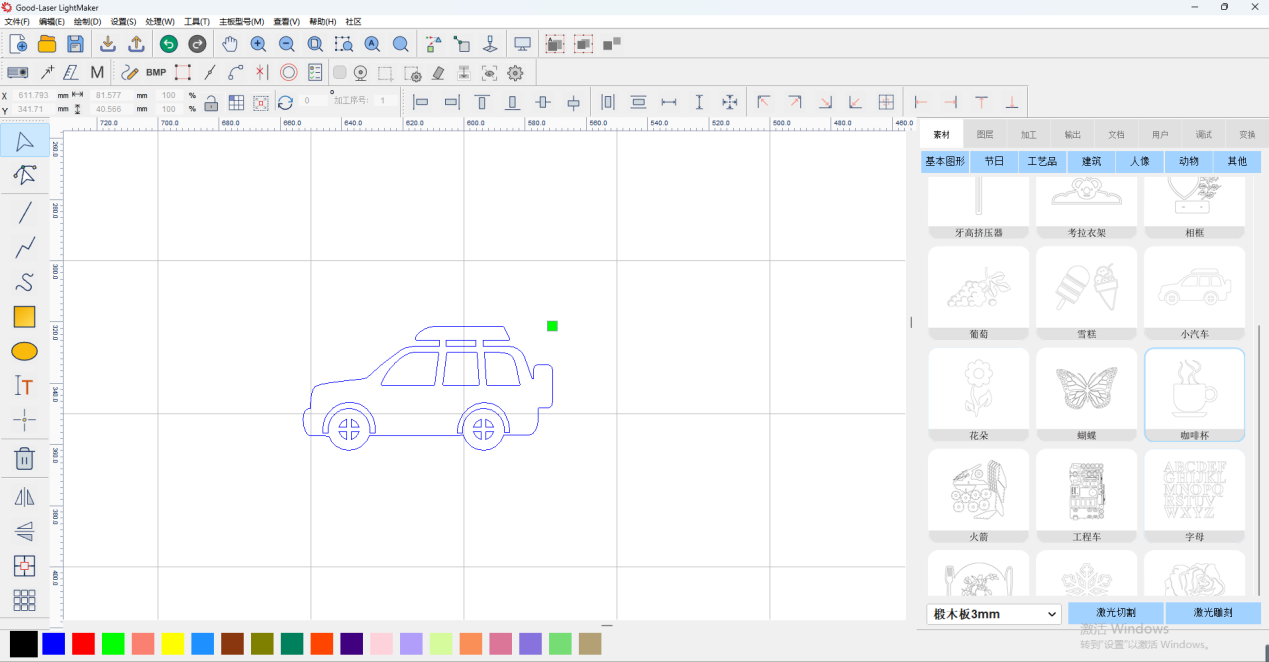

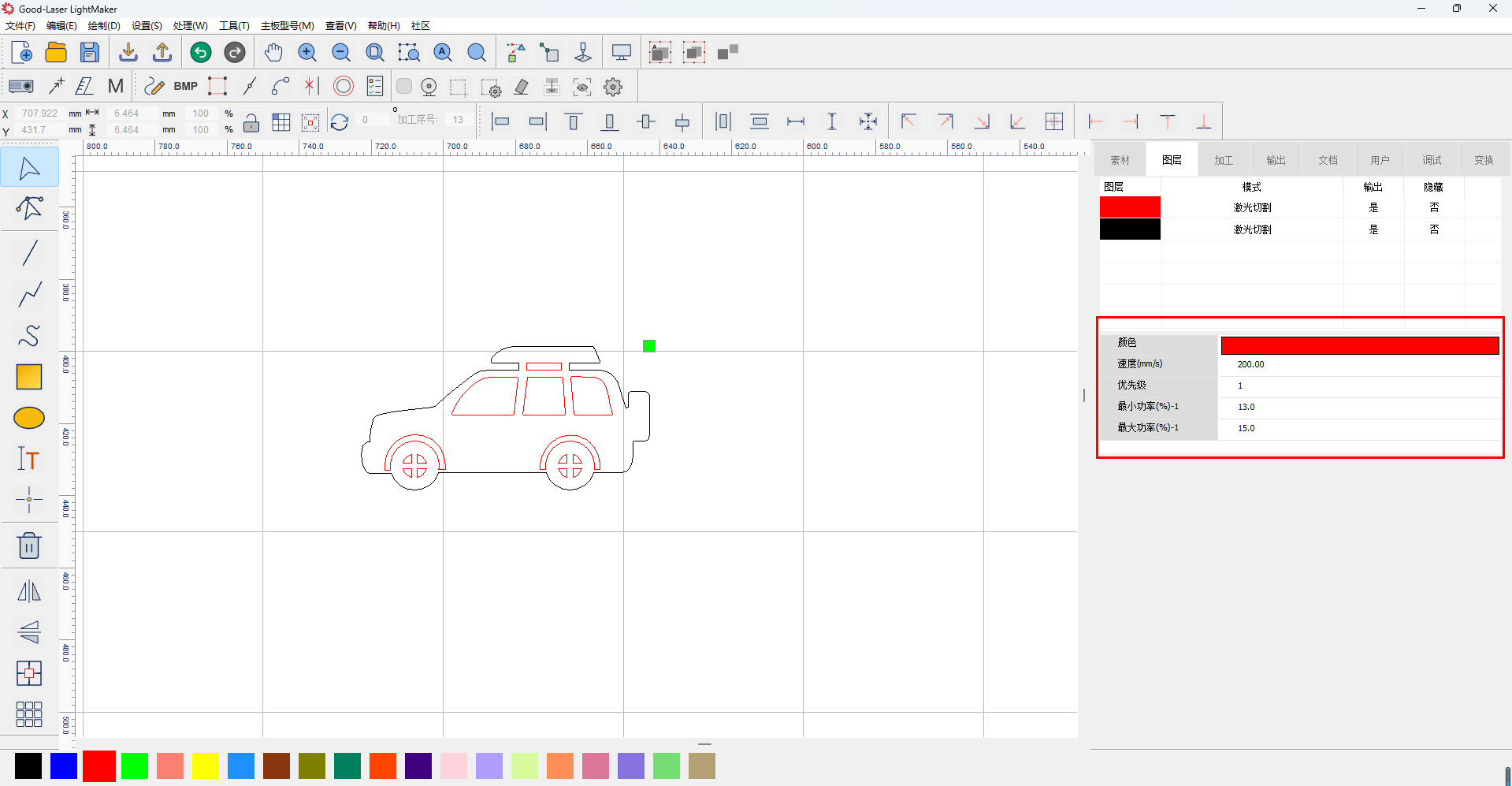

Software: Good-Laser LightMaker cutting software

Material: 3mm basswood, car drawings

Before starting work

Confirm that the laser is correct and the lens is clean

Make sure the exhaust fan is working properly

Make sure the air assist is turned on

Step 1: Import the file into the Good-Laser LightMaker cutting software, adjust the size, position and settings. Check to make sure everything is normal.

Step 2: Set processing parameters and cutting path

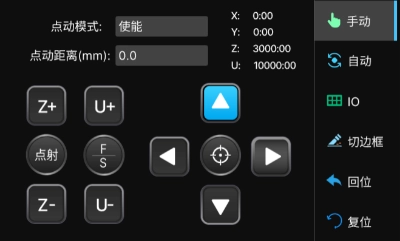

Step 3: Focus on cutting the wood board

To focus, two options are selected:

Auto focus: Click the [Auto] key in the operation panel, click to find focus, click [Border] to determine the processing range after auto focus, and click [Start] to process after confirmation.

If you prefer manual focus: click the [Manual] button in the operation panel, then click the up, down, left, and right buttons to move the laser head to the appropriate position, and click the [Location] button to determine the starting point of the processing.

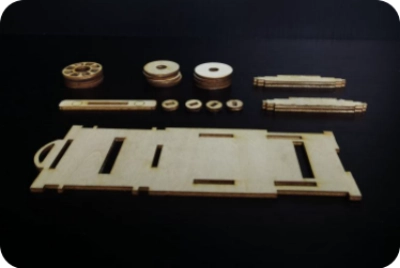

Step 4: Remove the cut parts after processing

After processing, press the pop-up platform to remove the workpiece

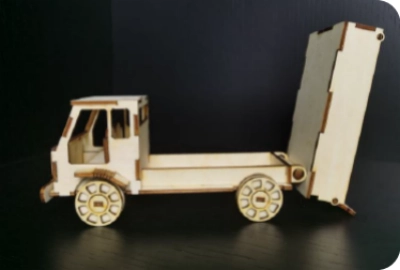

Step 5: Complete the splicing assembly

Come and try it!

We showed the production of car models, but creativity is endless. You can use Good-Laser equipment to create any image or pattern you like. Laser technology makes DIY more convenient and also gives wings to your creativity.

If you like this project, you can pay more attention to our website www.good-laseredu.com, which has more interesting projects. Thanks for reading!